Data Is the Great Equalizer

During a recent conversation with Drilling Contractor Magazine, our Senior Vice President, Subodh Saxena, emphasized that data is critical for decision-making and unlocking value in operations. He highlights that while experiential knowledge is highly valued in the industry, data is necessary when making decisions as it removes the implicit bias that can come with relying solely on experience.

Watch the full interview here.

Our data-driven approach to drilling addresses one of the industry’s biggest challenges: transforming significant amounts of downhole data into actionable insights that drive performance improvements.

Success in West Texas

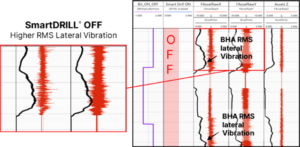

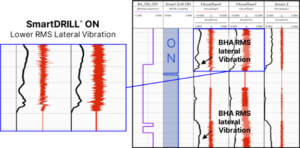

In a recent case study, our DrillView® high-resolution data collection tool was utilized in a three-mile lateral to validate an operator’s standard operating procedures (SOPs), evaluate SmartDRILL® automation’s impact on lateral shock and vibration, and establish best practices for automation programming.

DeepView® software revealed that with the automation enabled, lateral vibration was reduced by 61%, and there was less time off bottom due to the efficient ramp to full running speed.

What Gets Measured Gets Improved

Nabors ability to integrate downhole data with advanced automation allows us to derive actionable insights and make informed decisions in our operations.

- Nabors DrillView® Tool: This high-resolution data collection tool provided real-time insights into downhole conditions by measuring vibrations in key processes.

- Nabors DeepView® Software: Advanced software analyzed drilling data, revealing that while automation reduced vibrations, there were minor inconsistencies in slip-to-weight and weight-to-slips processes and slide-to-rotate transitions.

- Nabors SmartDRILL® Process Automation Software: Our experts tailored rig process automation recipes to further reduce lateral shock and vibration while maximizing the Rate of Penetration (ROP).

These targeted changes enhanced the operators’ SOPs and set the groundwork for fleetwide automation programming going forward.

Read the full case study here.

What Makes an Ideal Candidate?

As we continue to validate the importance of downhole data in operational decision-making, downhole data capture is becoming an essential practice for customers seeking to understand the most efficient drilling procedures to achieve optimal performance.

Compatible with Nabors and non-Nabors rigs, DrillView® downhole dynamics are ideal for customers running multi-well drilling programs, especially those who value making data-driven decisions. More specifically, it’s a valuable tool for customers looking to:

- Validate or create standard operating procedures (SOPs)

- Develop drilling windows and parameters to maximize Rate of Penetration (ROP)

- Understand the impact of automation on downhole tools

For those aiming to unlock the full potential of automation in their downhole operations, DrillView® provides the necessary data to improve efficiency, reduce operational risks, and achieve better financial outcomes.

To learn more about our Optimization Services, contact your Nabors sales representative.