Cementing & Casing Accessories

Nabors offers casing and tubular running services for both onshore and offshore applications. Additionally, cementing and casing products and accessories can increase value to casing running and cementing operations by improving hole conditioning, pipe movement, centralization, fluid velocity, and operational transition time.

Cementing and casing accessories include hydroform centralizers, Multi-Lobe Torque™ (MLT®) and Multi-Threaded Torque (MTT) rings, reaming shoes, and cementing solutions.

Hydroform centralizers

Nabors offers a proven alternative to conventional centralizers in challenging hole sections where pipe rotation may be required to reach total depth and/or during cementing operations. Hydroform centralizers feature a robust, patented design and attachment method. The unique blade design enhances circulation, hole cleaning and cementing. Nabors offers optional tungsten carbide hard-facing on blades for even more resilience when drilling in abrasive formations. Rotating and non-rotating centralizers are available.

Multi-Threaded & Multi-Lobe Torque™ rings

MTT & MLT® rings provide a positive make-up shoulder when installed in standard API connections. Nabors MTT & MLT® rings increase torque capacity, allowing the use of API casing and tubing connections in deviated wellbores which may have high torque requirements and prevent couplings and pins from erosion, sand, and abrasive flow. In fact, MTT & MLT® rings can increase torque capabilities up to three times in API connections.

MTT & MLT® rings also improve a well’s longevity by smoothing the J section from turbulent flow and protecting couplings from erosion. Nabors MLT® rings are made of L80 material; however, they may be manufactured in P110 or Q125 materials upon request.

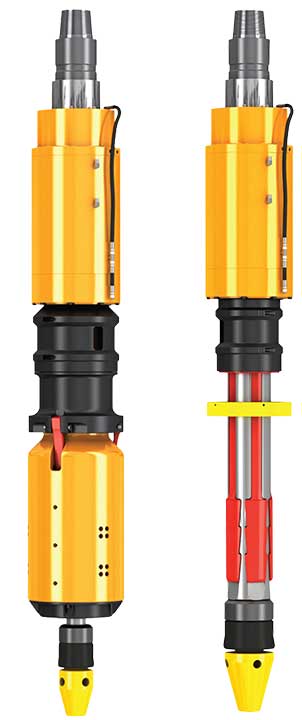

Reaming shoes

Nabors’ reaming shoes overcome challenging wellbore obstructions such as bridges, high local dog legs, cutting beds, ledges, sloughing formations, and deviated holes by smoothly and efficiently guiding the casing to total depth.

The latest model, XTRM, is designed with a unique guide nose to minimize the amount of material removed during drill out. Spiral blades help to condition the hole and provide centralization for cementing.

| Casing Size | Minimum Weight* | CRRT Blade Diameter | Length |

|---|---|---|---|

| 4 1/2 in. | 10.50 lbs | 5 5/8 in. | 29 in. |

| 5 in. | 13.00 lbs | 6 in. | 29 in. |

| 5 1/2 in. | 15.50 lbs | 6 7/8 in. | 29 in. |

| 7 in. | 23.00 lbs | 8 1/4 in. | 29 in. |

| 7 5/8 in. | 26.40 lbs | 9 in. | 29 in. |

| 8 5/8 in. | 28.00 lbs | 10 1/4 in. | 29 in. |

| 9 5/8 in. | 36.00 lbs | 11 1/2 in. | 29 in. |

| 10 3/4 in. | 40.50 lbs | 12 3/4 in. | 29 in. |

| 11 3/4 in. | 47.00 lbs | 13 3/4 in. | 29 in. |

| 13 3/8 in. | 54.50 lbs | 15 1/8 in. | 29 in. |

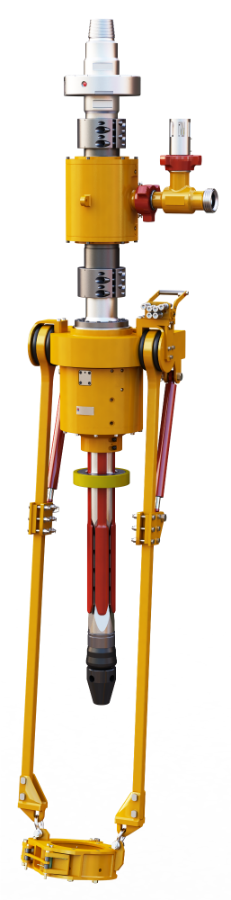

Cementing solutions

Engineered to compliment the Casing Drive System™ (CDS™), the Cement Swivel provides an entry port for the cement between the CDS™ and the top drive. This combination of equipment allows almost immediate transition from casing running operations to cementing, and it also allows the casing to be rotated and reciprocated during the cementing process.

Benefits

- Casing rotation while cementing

- Reduces NPT

- Improves mud displacement

- Reduces channeling

- Prevents gas migration

- Provides better zonal isolation

Features

- Smaller size takes up less derrick space

- Side port allows instant transition to cementing after running casing

- 2-½” bore allows easy flow of fluid and ball

- Portable tee auto plug launching system (addition)

- A 6-⅝” reg pin screws into the TesTork® or directly into the top drive, allowing rotation of the entire casing string during the cementing operation

- A 2-½” bore enables easy flow of fluids through the swivel via the top drive when rotation is not applicable and via side port during dynamic cementation

- Side port entry allows the flow of fluid while cementing and automatic ball launching using the ball launching assembly

- A 6-⅝” reg box connection attaches to the CDS™, enabling casing running operations while the swivel is in place and allows for immediate transition to cementing after casing running

Cement swivel

| Feature | Standard System Specification | Hi-Pressure System Specification |

|---|---|---|

| Load Rating | 600 Ton (with API 8C safety factor) | Same as standard |

| Bore Size | 2-½ in. | Same as standard |

| Temperature Rating | Shaft » -50 °C High Pressure seals » -23 °C |

Shaft » -50 °C High Pressure seals » -23 °C |

| Side Port Connection | 4″ Fig. 1002 Female Hammer Union (Threaded Side) | 3″ Fig. 1502 Female Hammer Union (Threaded Side) |

| Ball Launcher Connections | 2″ Fig. 1502 Hammer Union | 2″ Fig. 1502 Hammer Union |

| Ball Launcher Pressure Rating | 5,000 psi | 10,000 psi |

Cement Plug Launching System

| Feature | Standard System Specification | Hi-Pressure System Specification |

|---|---|---|

| Cement Plug Range | 4-½ in. to 13-³⁄₈ in. | Same as standard |

| Ball Sizes | 4-½ in. to 5-½ in. Casing » 1-³⁄₁₆ in. Ball 7 in. to 13-³⁄₈ in. Plugs » 1-½ in. Ball |

Same as standard |

| Packer Cup Pressure Rating (with safety factor ≥ 2:1) | 4-½ in. to 7 in. » 5,000 psi 7-⁵⁄₈ in. » 4,200 psi 8-⁵⁄₈ in. » 3,500 psi 9-⁵⁄₈ in. » 3,750 psi 10-¾ in. » 3,000 psi 11-¾ in. » 2,500 psi 13-³⁄₈ in. » 2,000 psi |

4-½ in. to 7 in. » 10,000 psi 7-⁵⁄₈ in. » 10,000 psi 8-⁵⁄₈ in. » 10,000 psi 9-⁵⁄₈ in. » 10,000 psi 10-¾ in. » 10,000 psi 11-¾ in. » 10,000 psi 13-³⁄₈ in. » 10,000 psi |

| Max Working Pressure | 5,000 psi | 10,000 psi |

| Max Rotational Speed | 50 rpm | 30 rpm |

| Connection | API 6-⁵⁄₈ in. Regular Pin Up API 6-⁵⁄₈ in. Regular Box Down |

API 6-⁵⁄₈ in. Regular Pin Up API 6-⁵⁄₈ in. Regular Box Down OR NC50 Pin Up NC 50 Box Dow |

Drill Smarter with Nabors

Tell us more about your needs by completing the form below and a Nabors representative will contact you soon.

"*" indicates required fields