Equipment Finder

RZR™ Rig Floor Automation Module

The iRacker® autonomous tubular handling system, offered in electric and hydraulic-powered units, enables completely hands-free pipe handling. Workers are no longer required on the rig floor to trip pipe.

Key Features

- Allows for offline stand building

- Modular desig for easyt installation on any AC rig with the use of two cranes

- Seamlessly integrates with the SmartROS™ control system, allowing the driller to control all rig floor operations from within the driller’s cabin

Robotic Pipe Feeder

The Canrig® robotic pipe handler is capable of automatically performing fast pipe handling, including spinning operations, on a drilling rig.

Key Features

- Fully electric, nine axis robot for pipe and casing

- Self-contained with hardware controls built-in for easy installation and integration

- Low maintenance requirement due to use of standard electric components and oilfilled gears

Robotic Pipe Deck Handler

The Canrig® robotic pipe deck handler picks up pipe, casing, BHAs and subs from either pre-loaded magazines, or directly from the pipe deck.

Key Features

- 3500 kg Lifting and Spinning Capacity

- Reduce Cycle Time, All-In-One Hands-Free Operation

- Fully Electric, Reduced Noise and GHG Emissions

Energy Efficient Lighting Solution

Canrig’s proprietary design, ILLUMIC lighting system, is designed to maximize worker’s visibility by illuminating the overall wellsite using energy efficient and maintenance free light-emitting diode, LED, fixtures mounted at the top of the mast on a custom bracket. The ILLUMIC system reduces noise, CO2 emissions, costs and man-hours related to relocating and maintaining multiple portable light towers on location.

Key Features

- Seamless installation with our custom crown-mounted framing

- Fuel savings of 29 gal/day with a reduction of 213 kw/hr to lessen carbon emissions

- Maintenance-free LEDs increase energy efficiency and reliability

- Lower energy consumption increases LED life span 10+ years

- Lower overall noise on rigsite when replacing light towers

- Automatic on/off capabilities based on available light, adding additional energy savings

Canrig® Sigma Top Drive

The Canrig® Sigma 500-ton top drive is the next generation top drive, completely reimagined to endure the harshest drilling conditions while operating with the highest continuous torque in its class. Designed to endure the harshest drilling conditions, this all-new, innovative top drive provides more power, performance and torque density than ever before, while enabling greater automation and remote-control capabilities – both at the surface and downhole.

Key Features

- High Torque Efficiency for longer lateral wells

- 30% less components for safer operations

- Advanced automation through seamless integrations

- 20db(A) reduction significantly decreases environmental noise

- 5-10% more energy efficient

Custom Integration

With over 20 years of experience in designing custom solutions for the oilfield industry, engineers are available to integrate top drives, catwalks, casing running tools or other equipment into any desired rig, including rigs of the future or older classes of rigs ready to see a new age of drilling

Key Features

- Service Loop Customizations

- Integrated & Split Block Options

- Rig Power System Integrations

Canrig® AC Top Drives

Canrig manufactures, markets and services a full range of electric top drive systems for most land and offshore rigs. This includes top drives in every size and configuration to meet any drilling application whether marine, desert, jungle or arctic environments.

Key Features

- Built-in capabilities for expanded drilling technologies with the Smart Suite of products

- Engineered and manufactured to API 8-C standards and carry the API monogram

- Available in portable, integrated and offshore configurations

- Established, dedicated parts and service team available to our customers through Rigline 24/7™

Casing Drive Systems

The Canrig® CDS is an adaptive and powerful casing running tool that serves many uses throughout casing operations. Whether the tool is used for an entire run, used for making up connections, as a fill-up tool, reaming casing, or just on stand-by in case of stuck pipe, the CDS can benefit any casing operation.

Key Features

- Field-proven slip design, patented link tilt pipe handling equipment, and a safety interlock system to maintain control of the casing

- Canrig’s global network of services provides 24/7 operational and technical support

- Provides the torque and ability to rotate and reciprocate casing to ensure it gets to the bottom

- Its compact design and light weight provide single mast rigs with safer operations and faster tubular running times

- The unit’s overall design makes it quick to rig up/down on a variety of different rig designs

- Engineered with field-proven technology for performance and serviceability

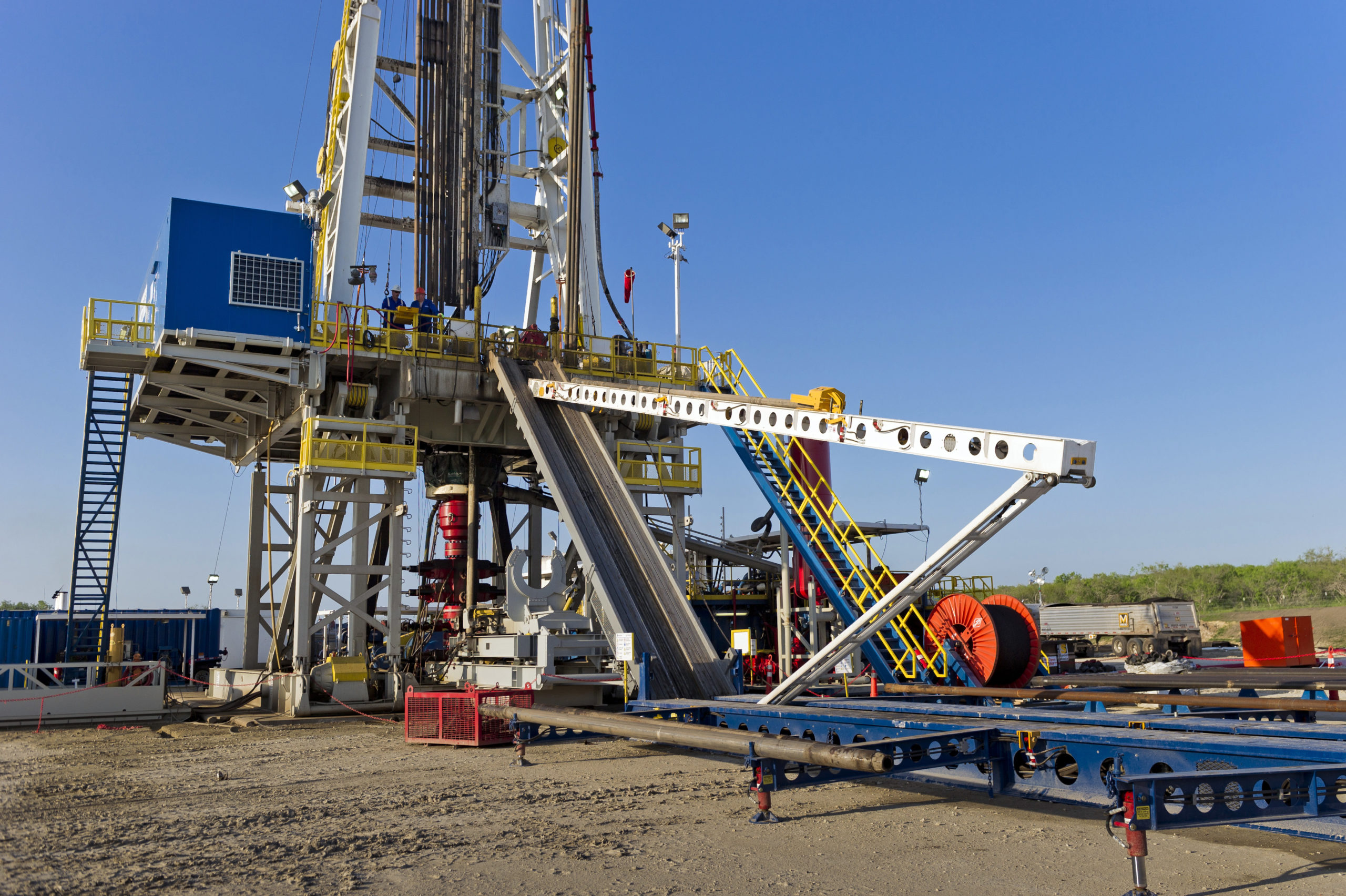

Catwalk

The Automated Power Catwalk C35 from Canrig is designed to individually index racked drill collars, drill pipe and casing into a center carrier where they can be lifted to the drill floor.

Key Features

- Prevent accidents by virtually eliminating human interaction with tubulars

- Remote control cabability

- Models are aviable to accommodate any tubular from pickup subs to 30-inch casing

Torq-Matic™ Wrench

The Canrig® Torq-Matic™ fully automated floor wrench with PLC control. Remote con- trolled capability allows the unit to be operated from the driller's console or from various rig floor locations.

Key Features

- Remote-controlled capability allows the unit to be operated from the driller’s console or from various rig floor locations

- Multiple system lockouts ensure instantaneous shutdown capability if an unforeseen event occurs

- Manual operation allows the operator to perform specific unique tasks and can be used in situations where automatic operation is not possible.

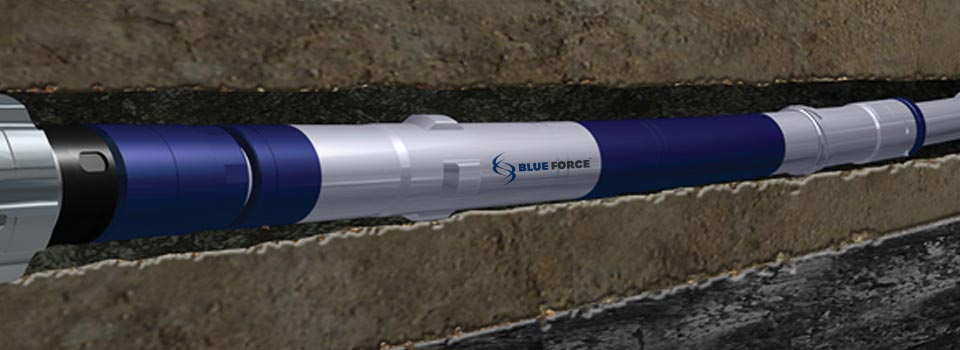

Mud Motors

Nabors’ Blue Force® mud motors are customized to specific specifications, built to withstand all drilling fluid types and temperatures, and can help reduce non-productive time.

Key Features

- Mud-lubricated bearing design – not affected by mud type or temperature

- Multiple power section configurations available to suit a variety of drilling environments

- Vertical drilling motors are available that can be configured for any hole size

PadWalker & Hydraulic Ramp Pivot

As pad drilling solutions continue to evolve and improve, walking rigs with crane-less rig-up are quickly becoming a typical feature on location. The Canrig® PadWalker™ was created to support multi-well pad drilling.

Key Features

- Simple in design, easy to maintain, affordable and may be retrofitted to existing catwalks

- Walking speed of 60 feet per hour keeps pace with existing rig walking systems

- Moves forward, backward, sideways or in diagonal directions and can be controlled wirelessly

Wireless Torque, Turn & Tension Sensor

Canrig’s wireless torque, turn and tension sensor, the TesTORK® sub, delivers high speed, precise data over a secure wireless connection. Designed for ease of use and field robustness, the TesTORK® sub meets the demands of tubular services companies and drilling contractors alike.

Key Features

- Real-time monitoring of torque load applied by the top drive during casing connections

- Rechargeable battery eliminates the need for expensive single-use batteries

- Operators can enter connection data of torque limits, turn values, and hold time for the shoulder and peak torque target

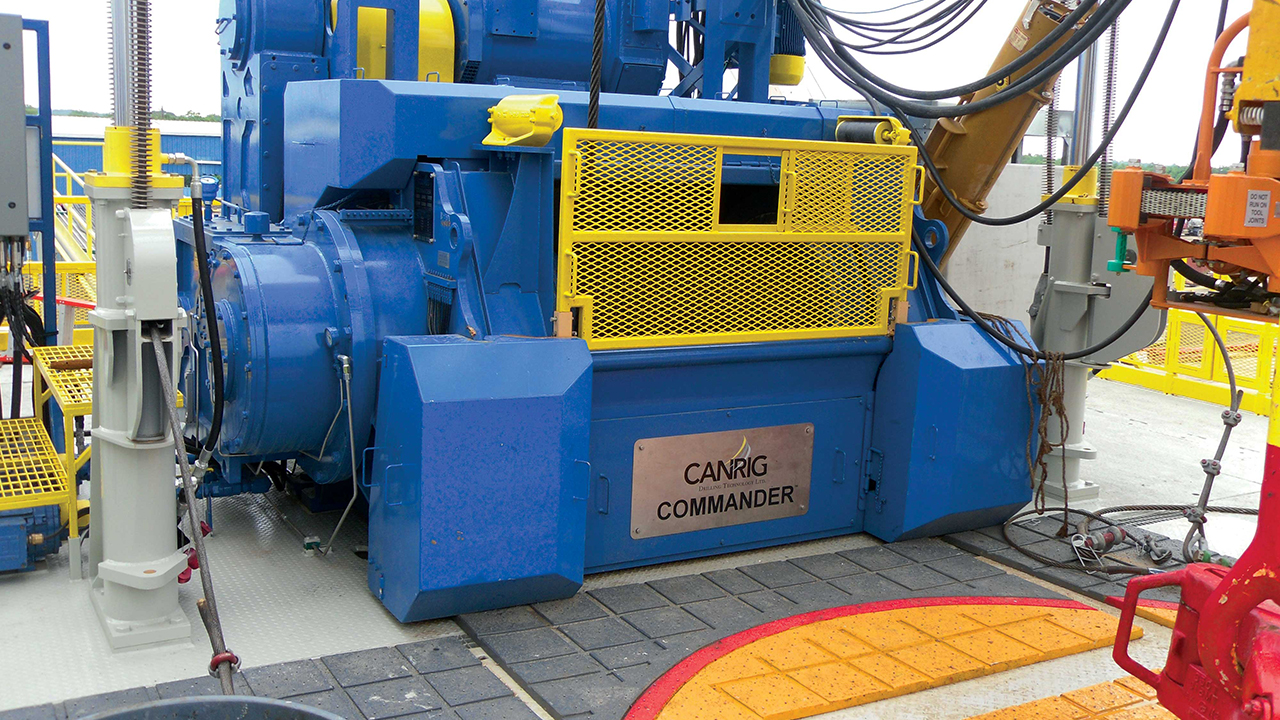

Commander™ Drawworks

The Commander™ Drawworks provides more than 50 design configurations, allowing customization of the number of motors and their power type, horsepower and layout, the number of speeds and the braking system.

Key Features

- Ability to use common components to customize performance for any application through configurable main gear box

- Innovative HPU Design

- Optional Friction BrakePlate or Caliper Brake

- Modular Design Model allows for field configurable; flexible orientation allows for motor repositioning to accommodate footprint and height profile needs and transportation limitations

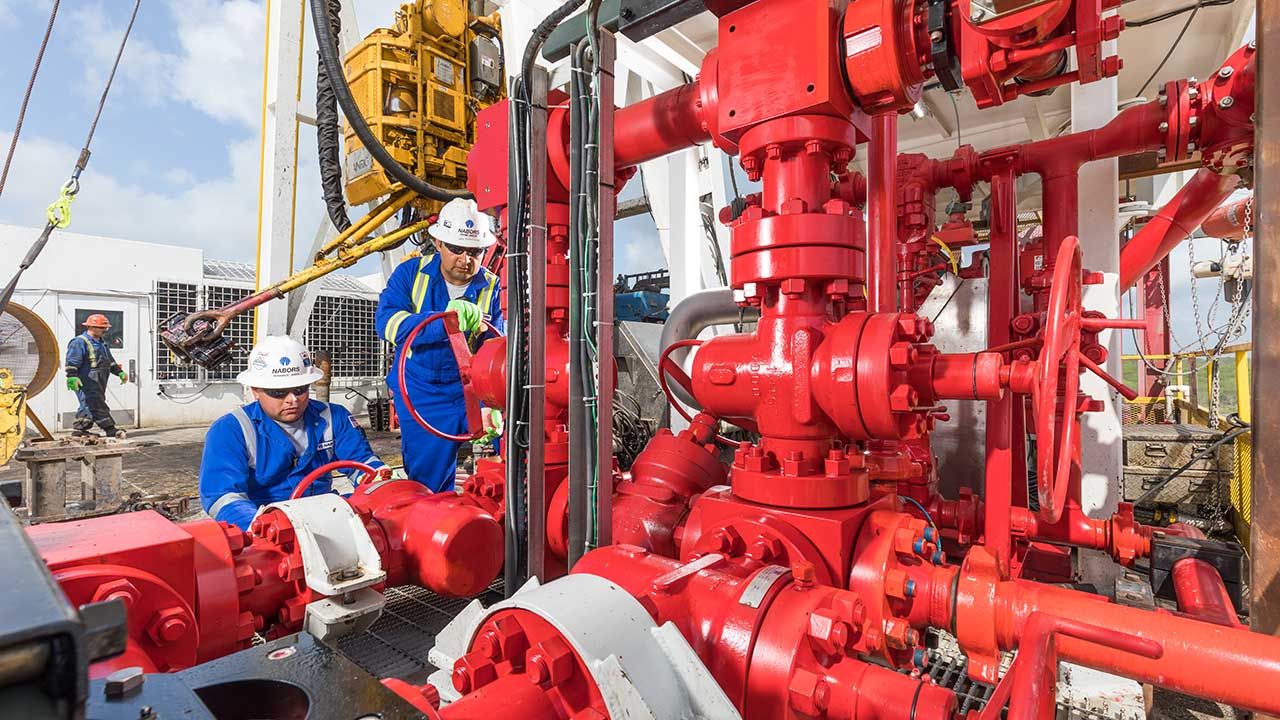

Integra™ Managed Pressure Drilling

Nabors’ fit-for-purpose managed pressure drilling (MPD) equipment and integrated MPD-Ready® drilling rig maximizes efficiencies and makes MPD services more scalable and cost-effective for unconventional land drillers.

Key Features

- Unique automated workflows eliminates the need for pre-job surveys and engineering, and minimizes high mobilization and rig-up costs.

- Elminates need for third-party service provider

- Increased safety, lower cost, reduced pad footprint

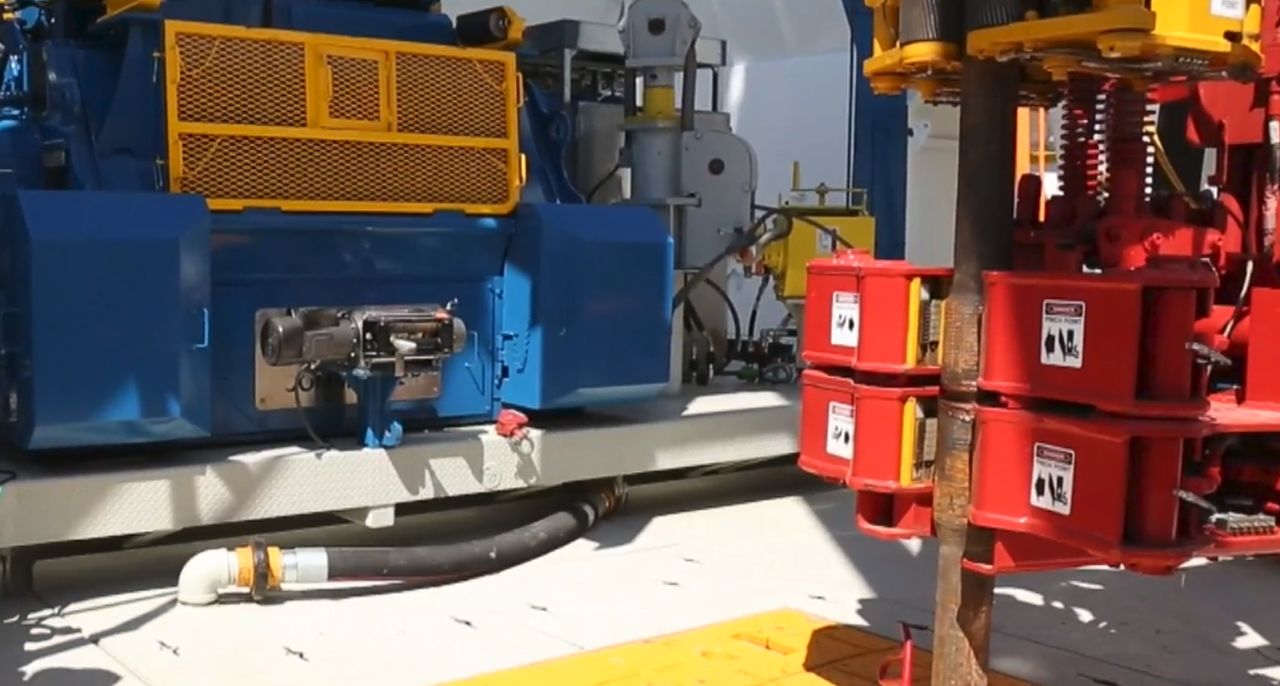

Electric and Hydraulic iRacker® System

The iRacker® autonomous tubular handling system, offered in electric and hydraulic-powered units, enables completely hands-free pipe handling. Workers are no longer required on the rig floor to trip pipe.

Key Features

- Allows for offline stand building

- Modular desig for easyt installation on any AC rig with the use of two cranes

- Seamlessly integrates with the SmartROS™ control system, allowing the driller to control all rig floor operations from within the driller’s cabin

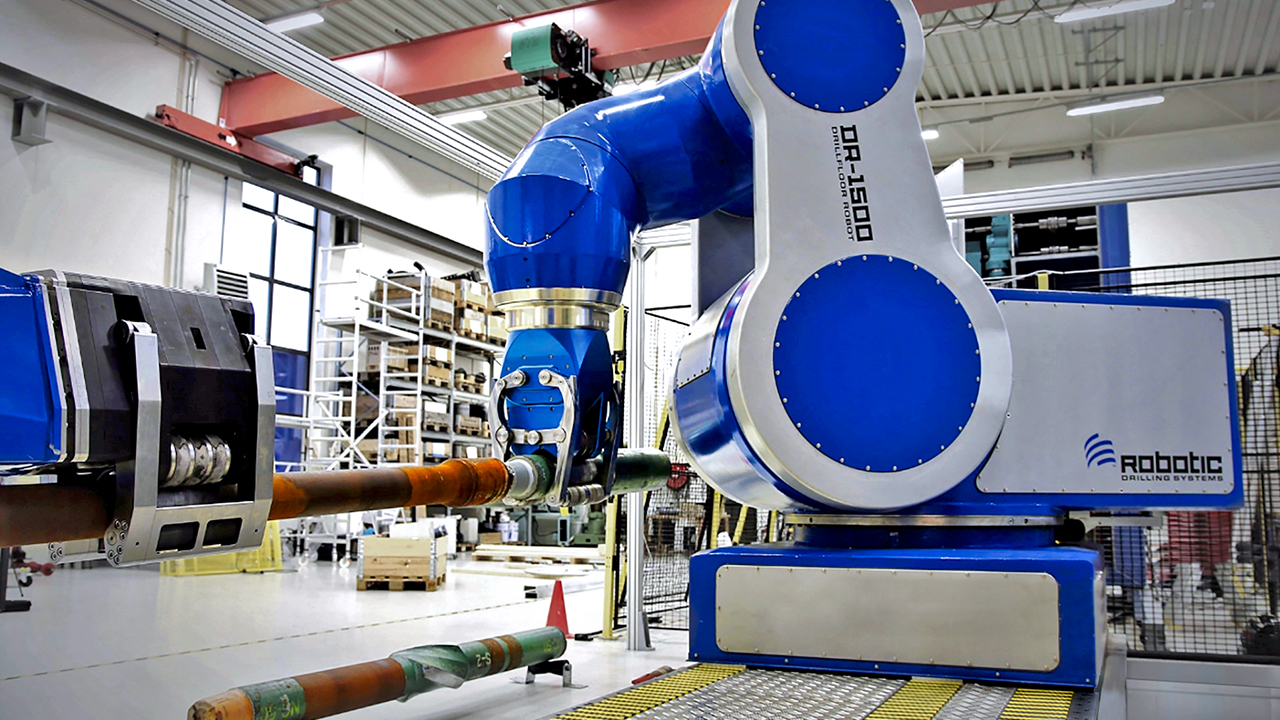

Robotic Pipe Handler

The Canrig® robotic pipe handler is capable of automatically performing fast pipe handling, including spinning operations, on a drilling rig.

Key Features

- Fully electric, nine axis robot for pipe and casing

- Self-contained with hardware controls built-in for easy installation and integration

- Low maintenance requirement due to use of standard electric components and oilfilled gears

Robotic Roughneck

In addition to enhancing the safety of drill floor activities, Nabors offers a fully automated electric, robotic roughneck for making precise connection during drilling operations.

Key Features

- Fully electric with 270 kNm capacity

- Self-contained with built-in controls for easy installation and integration

- Low maintenance requirement due to use of standard electric components and gears

Drill Floor Robot

In addition to enhancing the safety of drill floor activities, Nabors offers a fully automated drill floor robot system that reduces the non-productive time, noise, energy consumption and emissions typically associated with manual onshore and/or offshore drilling operations.

Driller’s Cabin

The Canrig® climate-controlled driller’s cabin provides integrated joystick control utilizing PLC technology. Touch-screen controls provide enhanced monitoring, control of rig equipment and visibility of drilling parameters.

Key Features

- Modular Design for ability to meet any rig design requirements; configurable for either land or offshore configurations

- Air or Liquid Cooled VFDS allows for higher power density and compact size

- Remote Access Capability allows monitoring of all systems and operations off-site

Power House

The power house is designed with flexible PLC input/output controls that can be expanded to accommodate any size drilling rig.

Key Features

- Modular Design for ability to meet any rig design requirements; configurable for either land or offshore configurations

- Air or Liquid Cooled VFDS allows for higher power density and compact size

- Remote Access Capability allows monitoring of all systems and operations off-site